Simply the Copa

The Fall 1994 Eurosport provides an interesting look into the production of a Copa Mundial.

Aside from providing a great selection of soccer gear, Eurosport has always produced interesting and unique articles to tie into the products they’re selling. I’ve always been interested in how things are maid. The behind the scenes look into a Copa Mundial from the Fall 1994 World Cup Edition was right up my alley.

I did not write any of the content…this all comes from page 4 of the Fall 1994 issue of Eurosport.

Enjoy!

When the world’s great players take the stage for the 1994 World Cup, over half of them will be wearing Copa Mundials. The fact that so many footballers choose the same shoe in a market flooded with quality boots is remarkable. Perhaps even more incredible is the fact that the Copa has remained virtually unchanged since its inception in 1978.

Innovations in shoe technology come and go. Cutting-edge materials are constantly being applied to soccer boots, be it the latest plastics in outsoles or synthetic upper materials. Yet, nothing has quite taken hold like the simple, understated Copa. While shoemakers are constantly reinventing themselves with new designs, Adidas’ plant manager Herr Heumann, who has been with the company for nearly forty years, says there is no reason to alter the Copa Mundial. When asked why it has remained such a popular shoe to this day Heumann doesn’t hesistate, “It’s the craftsmanship of the shoe. Everyone who works on the Copa knows the shoe inside out. That kind of experience and attention to detail makes all the difference in the world.”

Innovations in shoe technology come and go. Cutting-edge materials are constantly being applied to soccer boots, be it the latest plastics in outsoles or synthetic upper materials. Yet, nothing has quite taken hold like the simple, understated Copa. While shoemakers are constantly reinventing themselves with new designs, Adidas’ plant manager Herr Heumann, who has been with the company for nearly forty years, says there is no reason to alter the Copa Mundial. When asked why it has remained such a popular shoe to this day Heumann doesn’t hesistate, “It’s the craftsmanship of the shoe. Everyone who works on the Copa knows the shoe inside out. That kind of experience and attention to detail makes all the difference in the world.”

At Adidas’ shoe factory in Scheinfeld, Germany, 1200 pairs of Copas are produced daily.

The first step in the production of Copa’s is cutting the leather. Once all piece of the shoe have been cut, they are stitched together with the other parts of the upper such as the heel tab, tongue, stripes and logo.

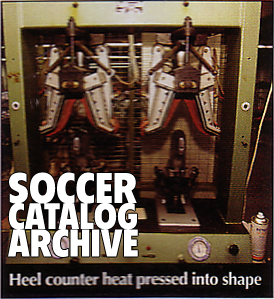

Once the upper is completed, it is placed on a machine that uses heat to mold the heel counter to the exact shape needed. The right side of the machine then freezes the heel counter to keep its shape.

Next a machine stretches the leather around the last and nails it to the lasting board. The last is a piece of plastic designed by the shoemaker to resemble a foot. The shape of the last determines the final fit of a shoe because the upper and outsole are shaped around it.

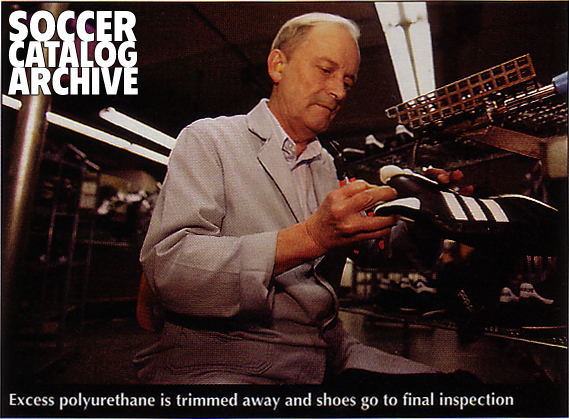

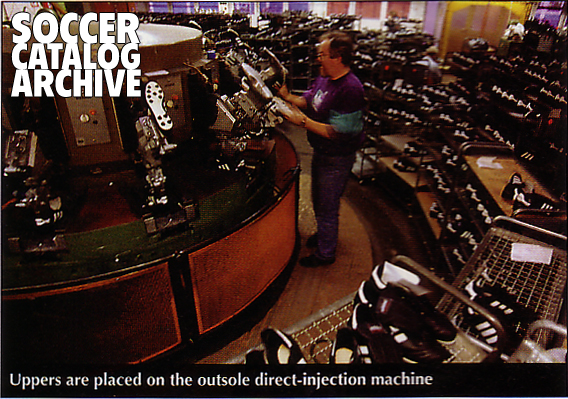

After the outsole has been bonded to the lasting board, studs are attached to the outsole using direct injection molding. Twelve rubber studs are placed in holes on this machine. The outsole is placed over the studs, and heat is applied to mold the studs to the outsole. After cleaning off the excess polyurethane, the insole is then glued inside the shoe. The shoe is then inspected for quality is is ready to leave the factory.

Leave a Reply